Career Interest

- Aerospace

- Application Engineer

- Automation

- Defense

- Design

- Product Development

- Renewable Energy

- Transportation

Strengths

- CAD (SolidWorks, AutoCAD, Autodesk, Rhino3D)

- Rapid Prototyping

- Matlab & EES (Engineering Equation Solver)

- Arduino

Professional Experience

Schweitzer Engineering Laboratories

Mechanical Engineer Intern, May 2018 – December 2018

SEL challenged my electronics packaging skills and designing parts for different manufacturing processes including: injection molding, stamping, die punching, and machining. At SEL, I completed various types of analysis including: FEA, thermal, tolerance, and frequency to determine part specifications. I gained hands on experience using testing equipment and through rapid prototyping. For every part I designed I also drafted in 2D to communicate the design efficiently with the machine shop/vendors.

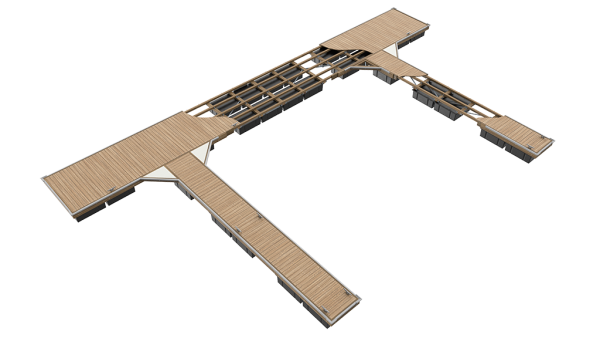

Bellingham Marine

Drafter, May 2017 – January 2018

Originally hired by Redpoint Structures in May, however, the company sold out to their contractor Bellingham Marine in August 2017. At Bellingham Marine, I continued to use SolidWorks and AutoCAD to design and draft floating structures. I worked on several types of docks for different clients including the City of Bellevue and Bainbridge Yacht Club. I also completed analysis to determine Freeboard and stability.

Undergraduate Research & Development

Research Assistant, January 2016 – May 2016

Assisted Dr. Arda Gozen with soft matter electronics. Through this experience I designed various tensile samples from various elastic materials. After tensile testing, I calculated material properties by analyzing and plotting the datasheets. The purpose of this research is to advance 3D printing to enable high flexibility for the medical industry and consumer wearables.

Engineering Projects

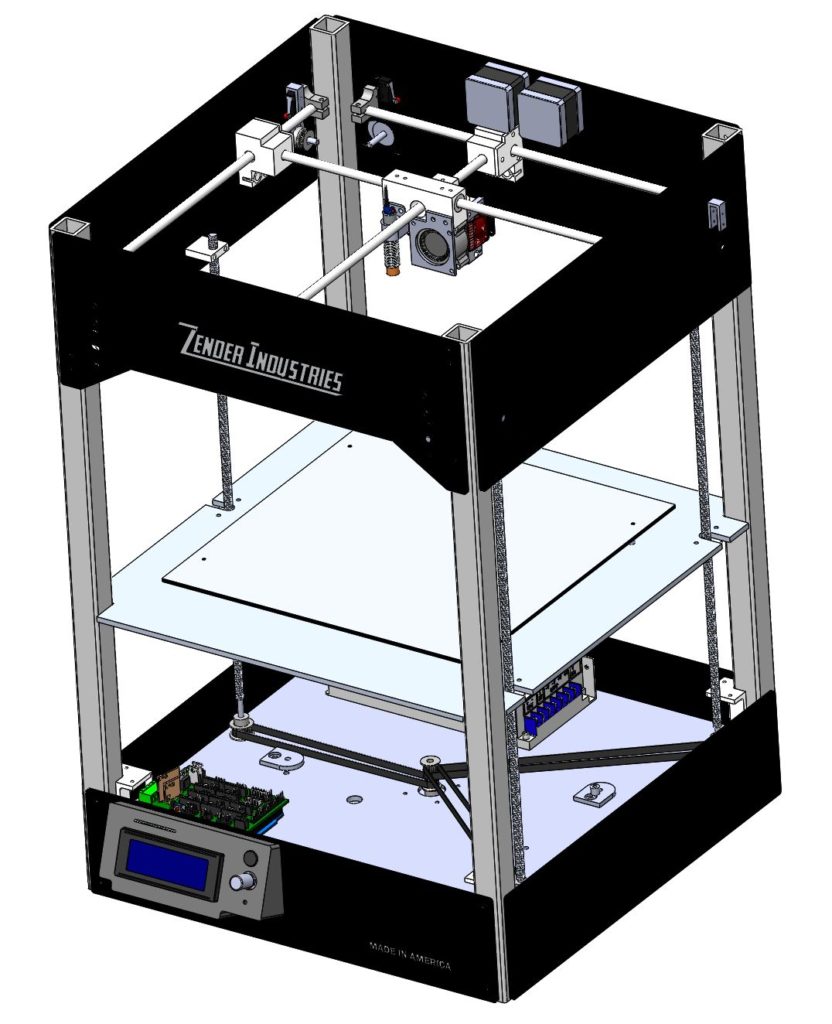

3D Printers

Designing and producing 3D printers has been my greatest hobby for the past 6 years. Initially, designing the printer was use to learn SolidWorks, but now I build printers to innovate new subsystems to improve the industry. Ideally, in the next few years I’ll have well developed printers and accessories to sell to friends and family as a side business to help pay off student loans.

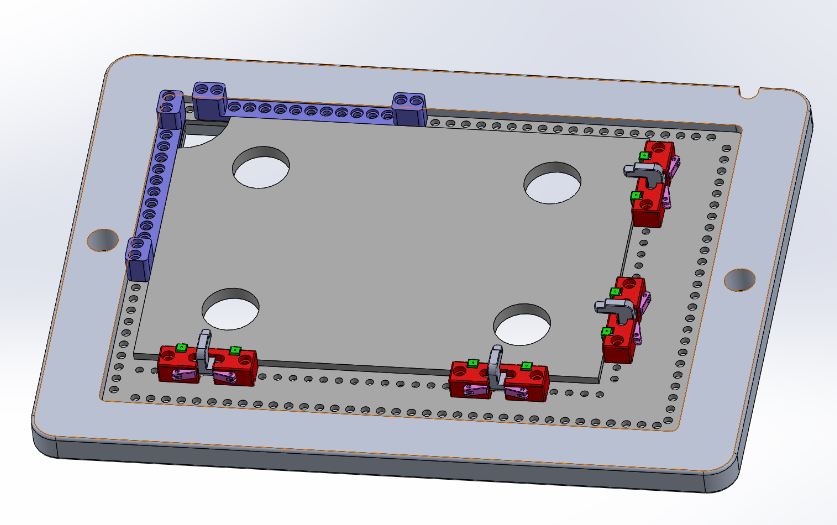

Microsoft Senior Design Project

For my senior design project, I was assigned to Microsoft who requested our team to design a new carrying device for their hardware in the manufacturing process. This device is used for all of their hardware products to be carried through the assembly process while automation machines and humans datum off it for precise pick and place. Prior to our team, each product required its own carrying device, now they only require one. This was a simple design project, however, it taught me a lot about tolerance stack up and rapid designing.

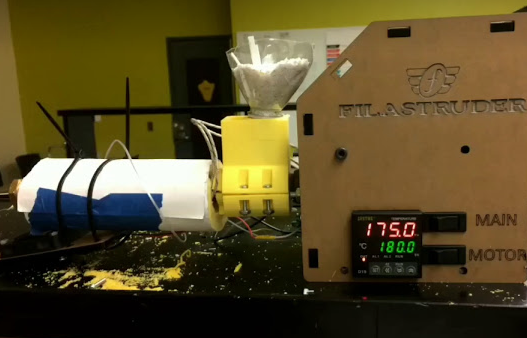

Polymer Extrusion Recycling System

I proposed this project to the WSU 3D Printing Club to develop a recycling program on campus and to make the club self-sustainable. This project was split up into three teams: shredder, extruder, and spooler. My focus was leading the extruder team. This recycling system is still in the making, and it has developed my project management skills and creating timelines.

Brick Extruder for Ugandan Village

My pre-CAPSTONE course introduced this project which split up an entire brick producing machine into subsystems. My group was tasked with designing and making the extruder portion. This brick extruder was designed for a village in Uganda with the goal to produce 20,000 bricks per day. This project enhanced my skills with flow analysis and technical writing skills.

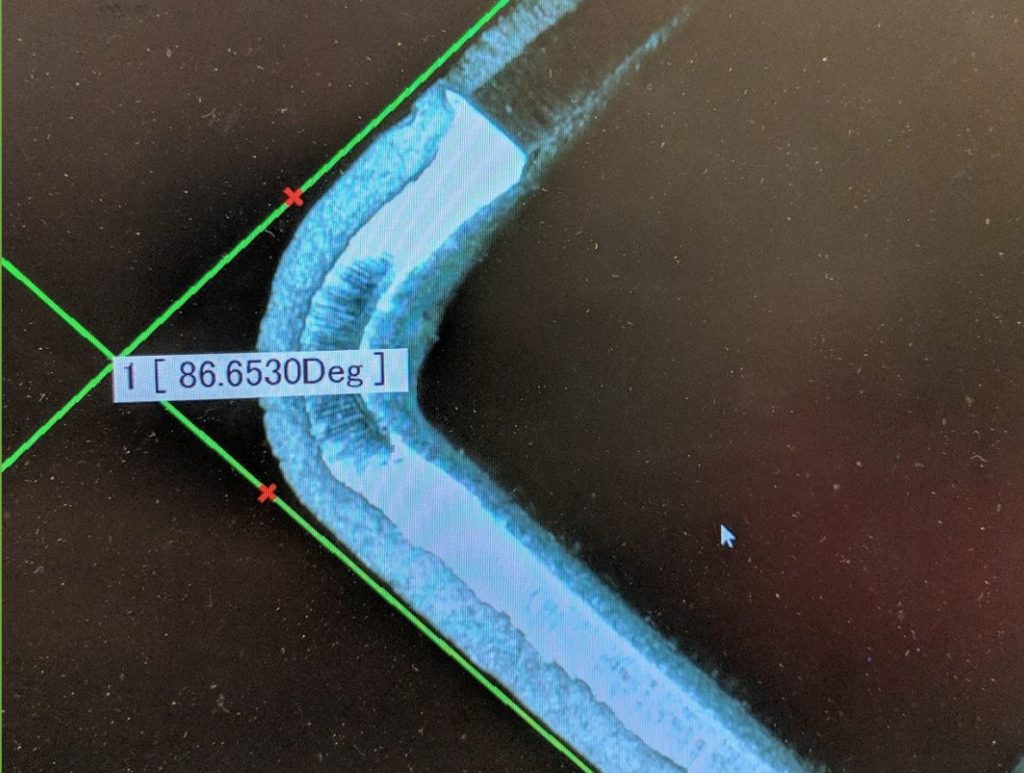

Cascadia Eye

Cascadia Eye was interested in designing their own brand of frames for prescribed lenses. They asked me to help reverse engineer competitors designs and then make changes to acquire their design requirements.

University Class Projects

Other Projects

Laser Engraving Fun

When John wants a stress free project, he turns to the laser engraver and makes various wall art for fun.