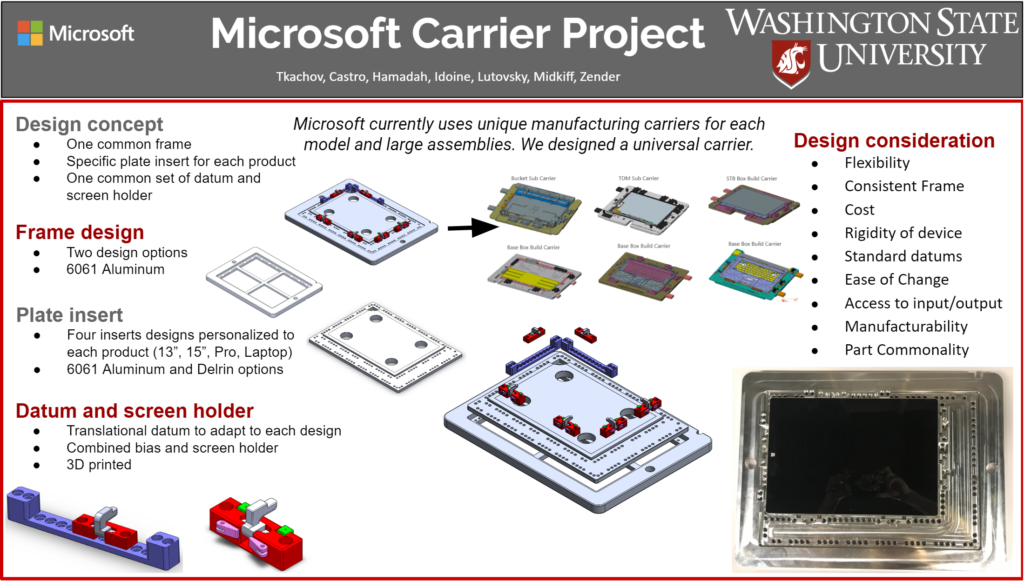

Universal Common Carrier

Microsoft use to use unique manufacturing carriers for each device/model and needed a common manufacturing carrier. Our misson was to create a new universal carrier that: reduce manufacturing costs, reduce environmental impact, unify design philosophies, and reduce fixture lead time.

Rapid Design

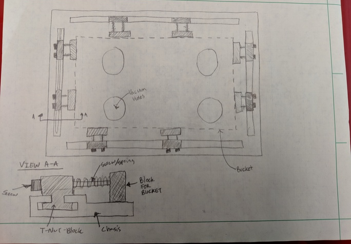

Our team started with indvidually coming up with “napkin” sketches (quick 10 minute ideas) and shared them all with each other for comparison. We rated each design with a pugh matrix to pick which ones we liked best and then made more sketches that were different than before.

After quick sketches we split into three teams, each with different goals in mind. The team I was on focused on universal parts.

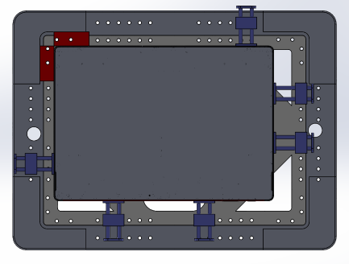

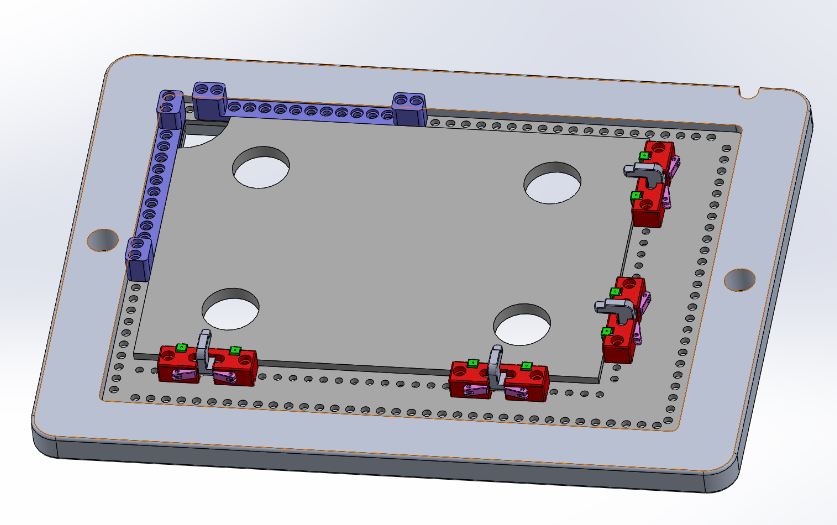

After consolidating a few rounds of designs, our team developed this design. From that point onward, we split into each team member was tasked to a part. I was tasked to the insert and helped with the frame due to another teammate having personal emergency.

Analysis

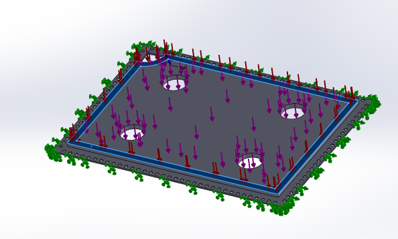

FEA

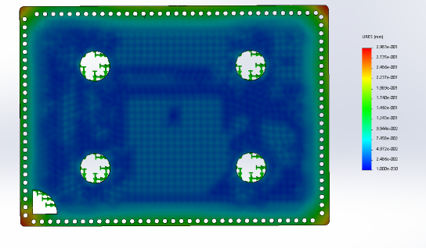

I simulated the forces of different manufacturing process on the insert plate to see how much bending the plate will go under and to verify there would be no plastic deformation.

Thermal

I ran a thermal analysis on the inserts to check for the coefficent of thermal expansion and to validate our pocket in the main frame was large enough for any tolerance stack up.

Testing

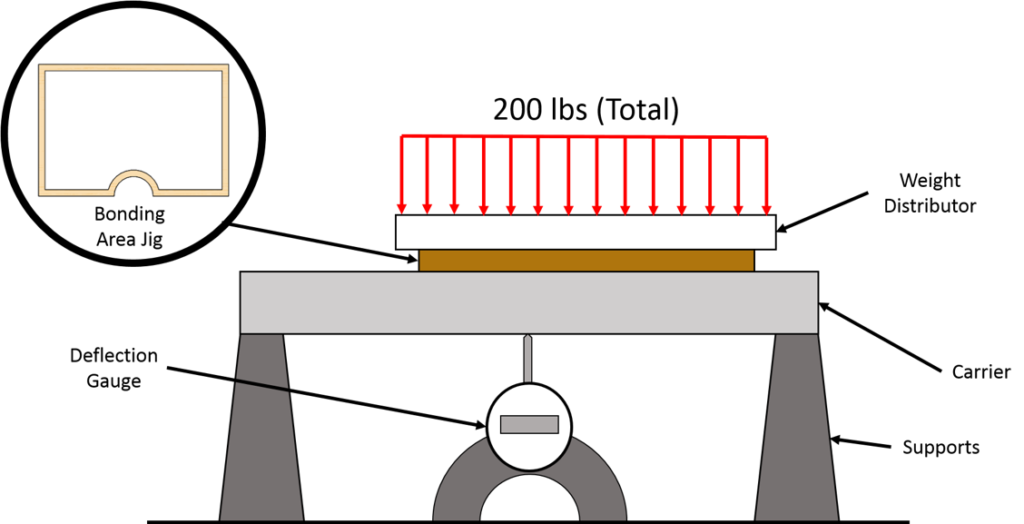

Every team member helped with validation testing. We simulated the pressure that would be applied to the adhesive bonding region and measured the amount of flex/bowing within the assembly.

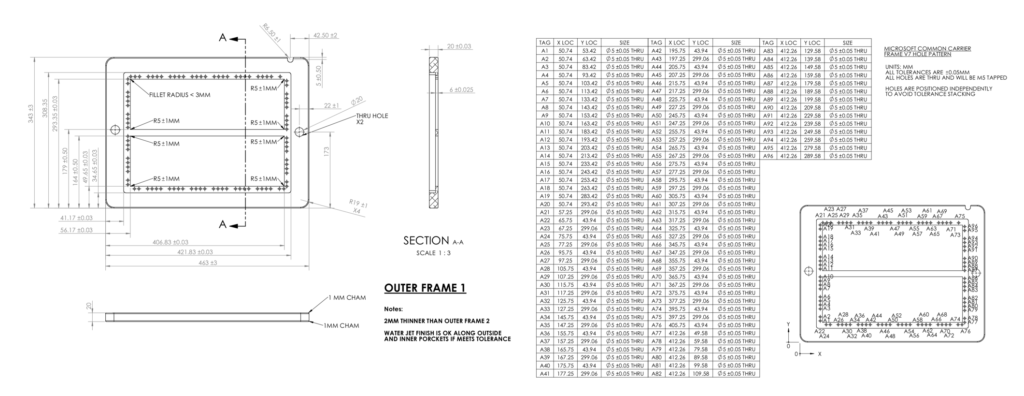

Drafting

Conclusion

Microsoft was very happy with our work and implemented it into their team. They showed us how to use the Pugh matrix, but after seeing how smoothly our design process went, they were encouraged to use it even more within their workplace.

I am grateful I learned a lot about tolerance stack ups and GD&T from this project, that knowledge provided great insight for my SEL internship immediately after.

To see the full project please download the presentation or written report.